In the European process industries large amounts of energy and resources are used to produce millions of tonnes of materials each year. Especially in metal making processes, metallic scraps from end of life goods are recycled and used as secondary raw materials in the processes. Usage of scrap is both ecologically and commercially beneficial, since it reduces the depletion of natural resources like virgin ores and avoids landfills with waste material. Today even more important is that the energy consumption and the CO2 emissions of the reduction processes of metal ores can be reduced or even totally avoided when using recycled materials as feedstock.

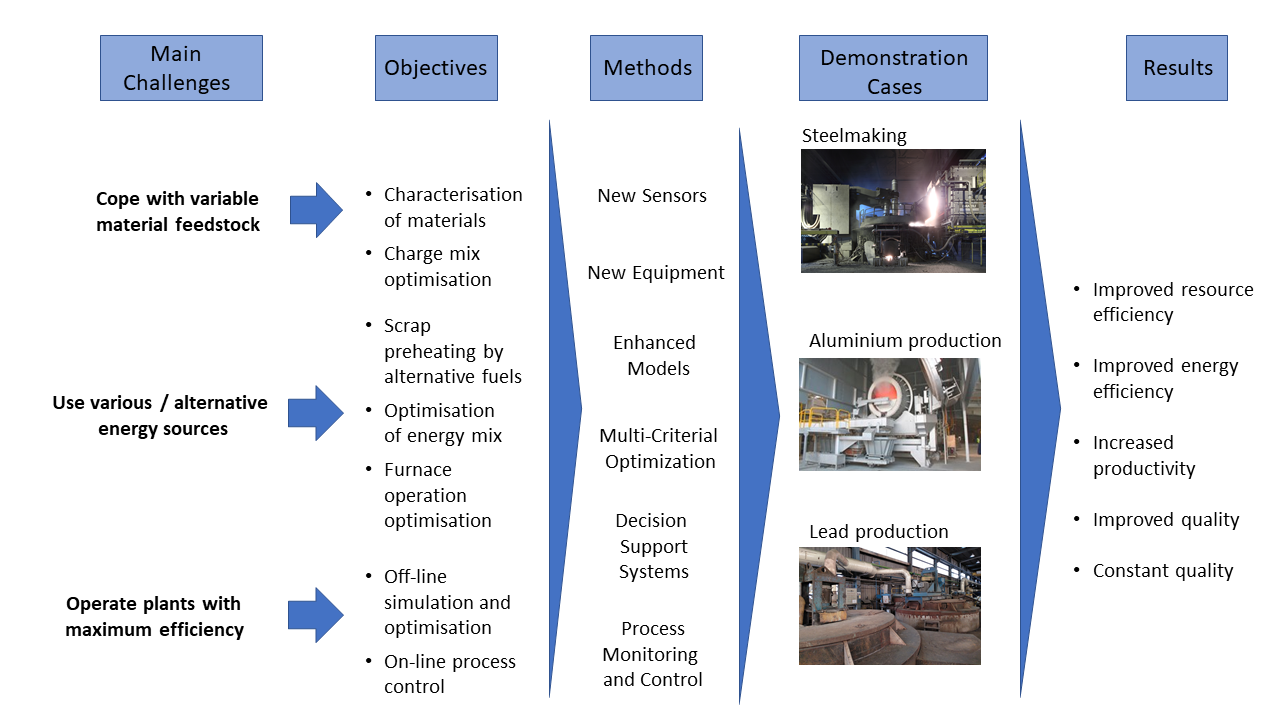

However, the metal production facilities are facing an increasing variability in material and energy feedstock. To cope with this challenge, existing metal production plants need to be retrofitted with appropriate sensors for scrap analysis and furnace operation, to cope with the varying conditions of the feedstock regarding materials and energy. Furthermore, the selection of the optimal feedstock in terms of material and energy efficiency has to be improved by application of appropriate process control and decision support tools. Also solid scrap preheating systems can increase the energy efficiency of the melting processes. To monitor and control the process behaviour in an optimal way, model-based software tools have to be developed and applied.

Thus, the objectives of the REVaMP project are:

- Development, adaptation and application of novel retrofitting technologies to cope with the increasing feedstock variability, and to ensure an efficient use of the feedstock in terms of materials and energy, by means of:

- Novel sensors for characterisation of metal scrap regarding chemical composition

- Metal scrap preheating system operated with waste derived fuel

- Software tools to model the operational input conditions of the processes

- Monitoring and control systems to optimise the processes for metal production at varying feedstocks

- Demonstration within three different use cases from the metal making industry:

- Electric and oxygen steelmaking

- Aluminium refining

- Lead recycling

- Evaluation of the retrofitting solutions in terms of economic and ecological effects, as well as cross-sectorial applicability in other process industries

- Valorisation, dissemination and exploitation of the project results for the process industry