Aluminium refining

In Aluminium refining, different kinds of old Aluminium scrap are melted to produce, mostly, casting alloys for foundries, supplied according to standards and/or customer specifications. In one of the refining plants novel sensors for analysis of the incoming scrap types will be applied. In the second plant a sensorised scrap preheating system will be installed. Both plants will be equipped with model predictive control and decision support systems to optimize melting processes, for varying charge mix and energy efficiency, respectively.

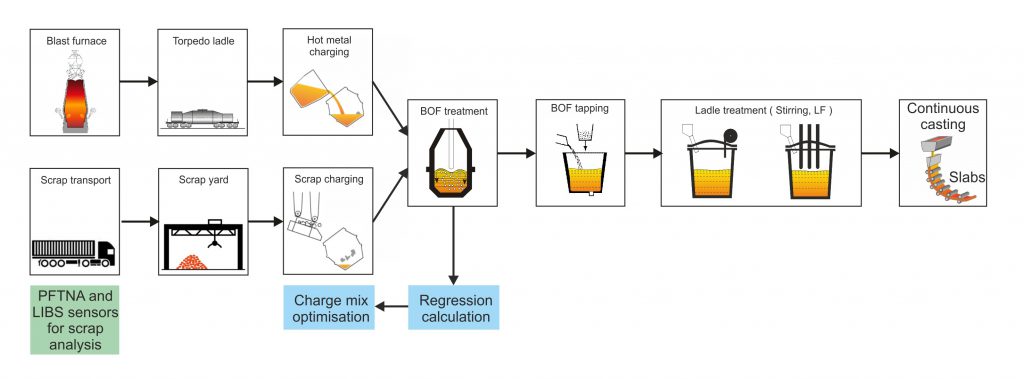

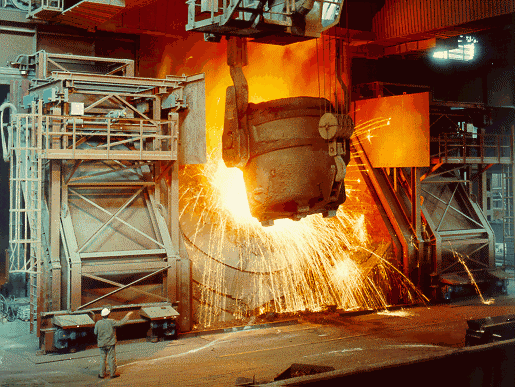

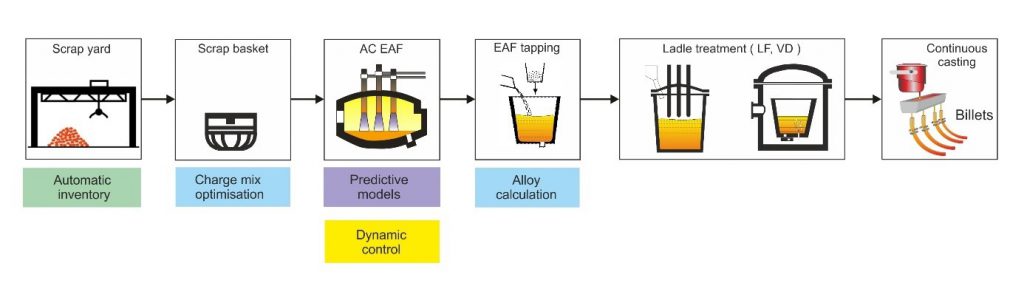

Liquid steelmaking

In liquid steelmaking, scrap is one of the most important metallic input materials. Novel sensors for characterisation of the composition of different scrap types will be applied, to enable the selection of the quality and cost optimal scrap mix. Decision support and model-based control tools will allow to operate the melting processes in oxygen and electric steelmaking in an energy and resource efficient way.

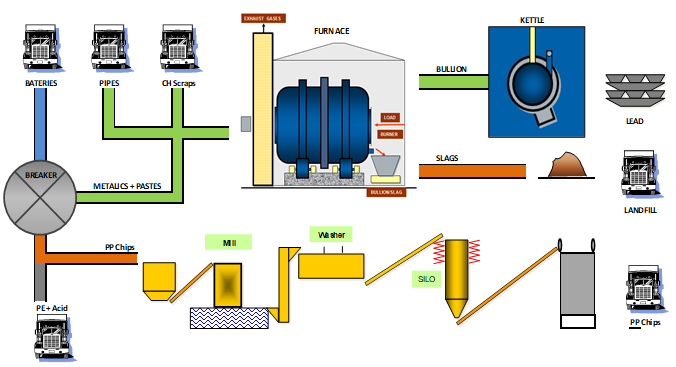

Lead production

The lead production process is based on the recycling of lead batteries and other lead containing scrap. Novel sensors will be applied for monitoring of the pyrometallurgical process and for scrap characterisation. Furthermore model-based monitoring and control tools will be applied to improve the process efficiency.