Results of REVaMP in Brief

Achieved Impact

In REVaMP, important steps for a significant progress beyond the state of the art of the metal making industry have been performed, especially regarding the successful industrial application of novel sensors, two types of neutron activation and a smart LIBS sensor, for in-line analysis of the metal scrap composition. These sensors provide the basis for a more thorough and reliable analysis of scrap properties, to increase the value in use also of low-quality scrap types and thus to enhance circularity of metal making processes.

Also, the industrial test of model-based decision support and process control systems for the different metal melting processes is an important step forward to the digitalisation of these processes, enabling a more efficient use of energy and resources which leads to relevant savings. Finally, the novel Alu-Q© multi-measurement system allows a near real-time assessment of important quality parameters of aluminium melts. All these sensors and software tools are subject of exploitation activities of the respective partners.

The project results provide the following impact for the involved metal making industries:

- the energy efficiency of the involved processes increased on the average by 8.5 % for the ensemble of REVaMPed solutions.

- the improvements in resource efficiency strongly vary with the use cases. The achieved values are in the lower range of 1 % for the steelmaking processes, and reach more than 10 % for aluminum production and 5% for lead production.

- The CO2 emissions were reduced for electric steelmaking by 5.9 %, for aluminium refining by 2%, and for lead production by 8.7 %.

- Reduced OPEX costs and increased productivity are closely connected with the increased use of low-quality scrap and a reduction of out-of-spec production by a better control of the charge material properties. Achieved saving values range vary from 2,43 €/t for oxygen steelmaking, 6,57 €/t for lead production and 16,76 €/ t for electric steelmaking. For aluminium refining OPEX savings lie around 2%.

- For all use cases, the payback period of the retrofitting solutions is well below five years.

The socio-economic impact lies in the reduction of CO2 emissions of the energy intensive metal making processes. In addition, the social impact in terms of acceptance of the retrofitting solutions by the different users in the plants was confirmed by the evaluation of a questionnaire. Finally, the cross-sectorial transferability of the retrofitting solutions was assessed, indicating that many of them can be transferred to other branches of the process industry with only small adaptations.

Results included in Public Deliverables

Deliverable 1.1 – Variability of Feedstock

Deliverable 1.4 – Challenges Scope of LCA

Deliverable 2.5 – Material Flow Analysis created

Deliverable 3.3 – LIBS sensor tested with scrap samples at laboratory and ready for installation

Deliverable 4.1 – On-line monitoring systems

Deliverable 4.5 – Software as a Service tool for Furnace Performance Management

Deliverable 5.1 – Charge mix optimisation implemented in steel plants

Deliverable 5.2 – Material flow analysis for steel plant

Deliverable 6.5 – Material Flow Analysis applied and validated for aluminium plant

Deliverable 7.4 – Material Flow Analysis applied and validated for lead plant

Deliverable 8.1 – Technical evaluation of the different retrofitting solutions

Deliverable 8.2 – Preliminary economic assessment

Deliverable 8.3 – LCA for assessment of environmetal impact reduction

Deliverable 8.4 – Report on cross-sectorial transferability of retrofitting solutions

Deliverable 9.1 – Project web site leaflet press releases

Deliverable 9.3 – Final-exploitation-workshop

Deliverable 9.4 – Joint-dissemination-workshop-with-other-projects

Results reported in Open access publications

Comparative Study of the Metallurgical Quality of Primary and Secondary AlSi10MnMg Aluminium Alloys

Data Augmentation and Feature Engineering for Machine Learning in Neutron Activation Analysis

A system for Elemental Analysis of Aluminium Chips, based on Neutron Activation Analytics

Characterization of large 5×5 inch BGO detectors with light readout by means of R11833-100, 5 inch photomultiplier

Model-based Decision Support System for EAF online Monitoring and Control

Comparison of Detectors with Pulse Shape Discrimination Capability for Simultaneous Detection of Gamma-rays, Slow and Fast Neutrons.

Combustion of a Solid Recovered Fuel (SRF) Produced from the Polymeric Fraction of Automotive Shredder Residue (ASR)

Exploitable results

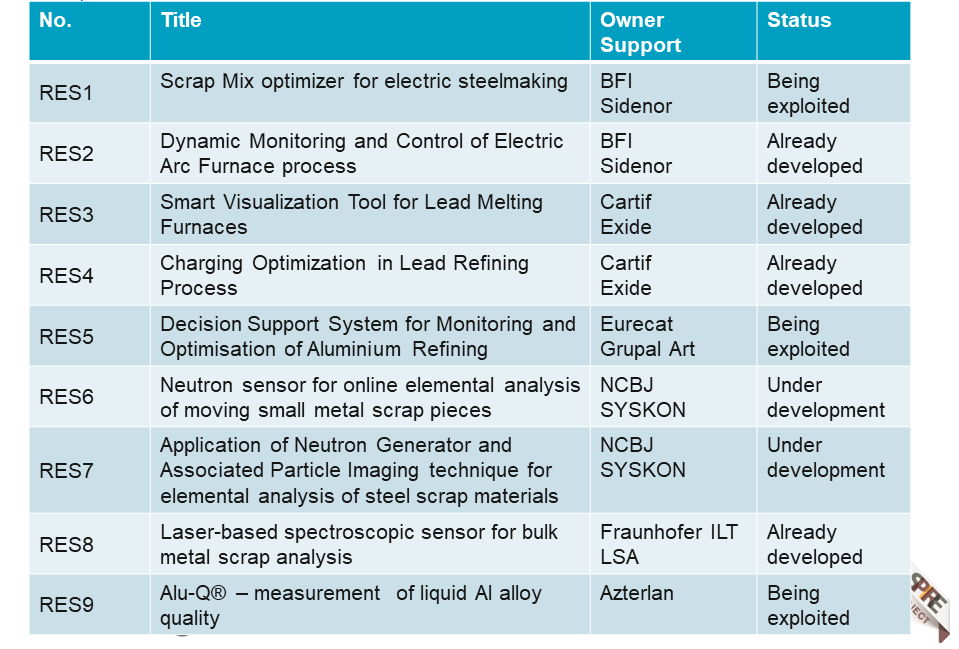

In the REVaMP project, nine innovative and exploitable results were developed, applied, tested and validated. The table below gives an overview on these exploitable results with names of creators and status of exploitation. The exploitable result No. 9 is already advertised on the market, see the link below the table.

AZTERLAN Alu-Q® Melt Quality multi-measurement instrument for Aluminium Alloys